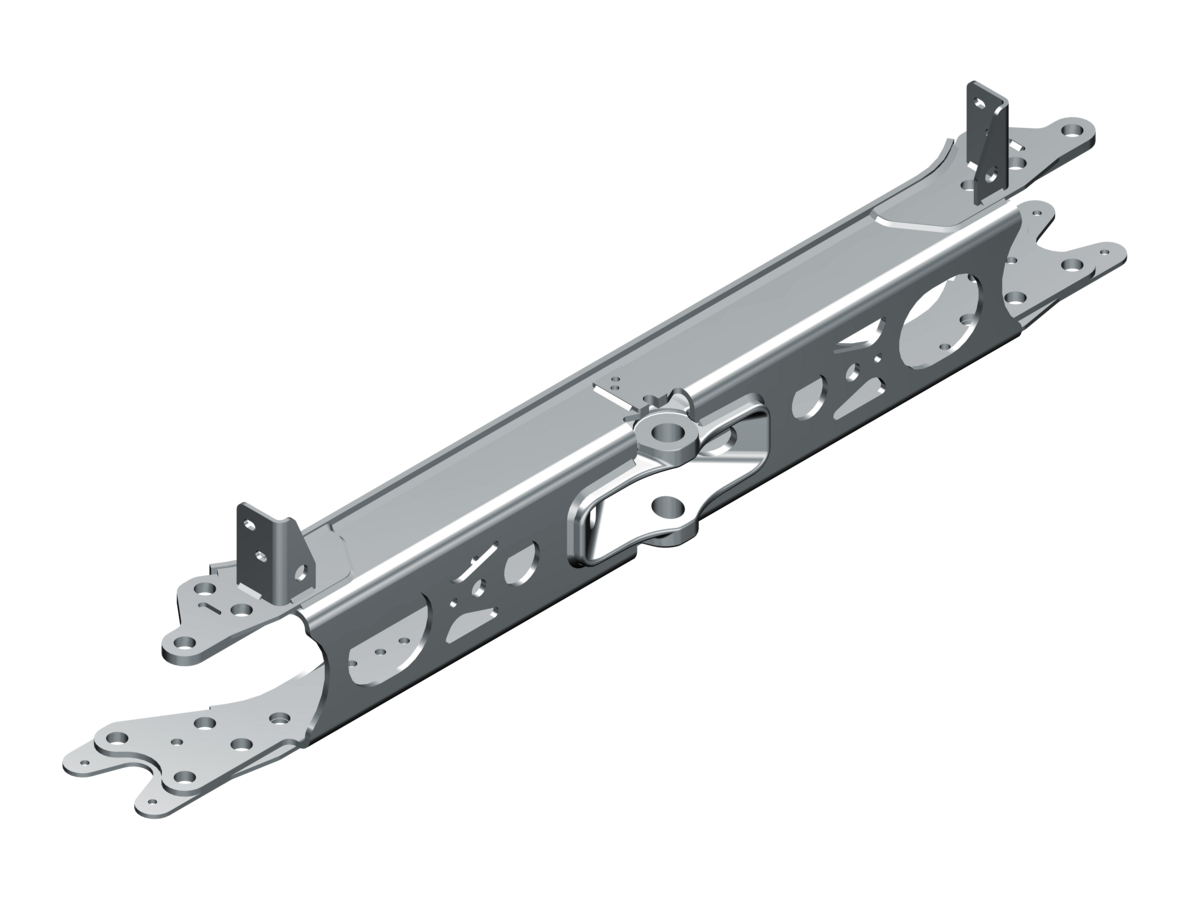

Front Cross Member

The cross member for the vehicle frame is not only a functional component but it is also critical for the dimensional stability of the pre- and final vehicle assembly. The front cross member also has load-bearing requirements for towing. Crash and durability are key requirements for this assembly.

With more than 5m of weld length, there are heat influences which can affect the final assembly dimensions. Weld sequences and part clamping concepts have been developed to control the heat induced influences to produce a part with high quality and high dimensional capability. The basic part is designed in a way to compensate the heat distortion by over-bending the single part in the stamping die.

Front Cross Member with Coupling Jaw

Technologies: Progressive die and transfer tool for producing the single parts, robotic MIG welding process, e-coating

Production plant: Iserlohn/Germany

Model/Customer: Mercedes-Benz Trucks Actros

Challenge: Customer support during the component development stage and the design of the forged part (coupling jaw).