Competitive Tool Shop

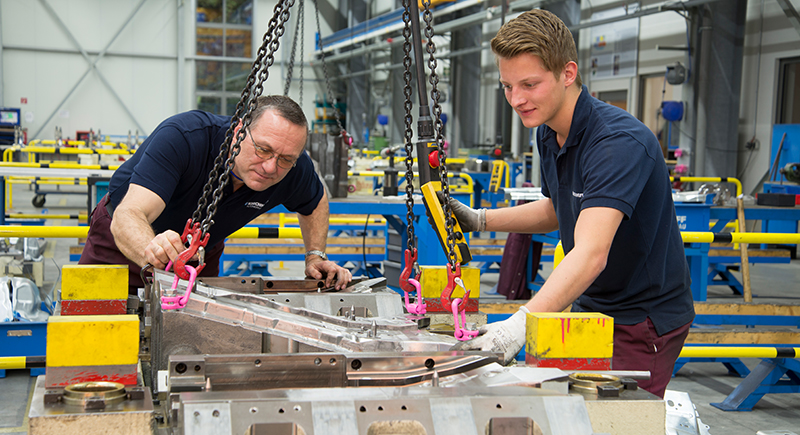

The tool shop is a fixed component of KIRCHHOFF Automotive in Attendorn, and has been for more than 40 years. Roughly 60 employees construct and manufacture prototype, single, progressive and transfer tools for cold and hot formed structural parts based on customer requirements in the automotive industry. By focusing on core competencies which are crucial for a competitive tool shop and the production of tools for complex components the tool shop has a technological advantage.

This does not only apply to tools for single or two-step hot forming. Also in the production of forming tools for the production of sophisticated components made of high-strength materials with up to 10mm thickness for the commercial vehicle industry, our tool construction in Attendorn looks back on decades of experience. Take advantage of our long experience in the design and construction of complex forming tools. The high proportion of tools from Attendorn used in our own worldwide production facilities and the resulting success of our company group is another argument in favor of our tool shop's efficiency. Ask us or arrange a visit with us in Attendorn.

In the course of the reconceptualization of the tool shop and continuous process optimization, the decision was made in 2008 to combine the three existing tool shop locations into one future-oriented tool shop located in Attendorn. In 2013, the project came to fruition in Attendorn with a new hall. A modern tool shop with efficient structures enhance our service portfolio at KIRCHHOFF Automotive. To enhance competitiveness, the tool shop now operates with synchronous and clocked manufacturing. The unique layout of the tool shop proves efficiencies in every step. This does not only lead to shorter cycle times, but also offers greater flexibility with regards to the production of new tools.

Data and Facts at a Glance

- Modern toolmaking with efficient structures

- 40 years of experience, roughly 60 employees

- Prototype, single, progressive and transfer tools for cold and hot formed structural parts for the automotive industry

- Forming tools for the commercial vehicle industry

- Synchronous and clocked production

- Particularly short throughput times and high flexibility

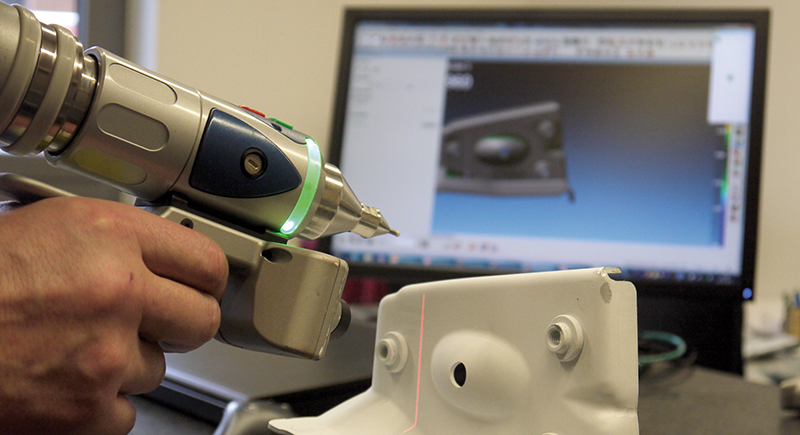

- Quality, adherence to delivery dates and cost transparency through tool construction-specific project management